|

Great Wall Heavy Industry Machinery Co., Ltd

|

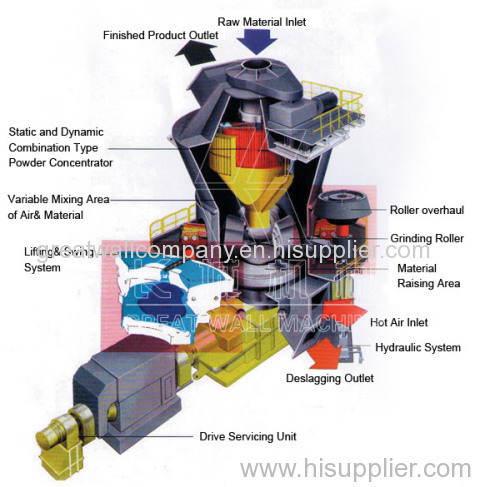

Great Wall Vertical Roller Mill For Sale

| Payment Terms: | T/T,L/C,D/A,D/P,WU |

| Place of Origin: | Henan, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

The vertical roller mill is widely used in the fields of cement, electricity, steel, nonmetallic ore, etc., it can grind cement raw materials, slag .

The vertical roller mill is widely used in the fields of cement, electricity, steel, nonmetallic ore, etc., it can grind cement raw materials, slag, coal, etc. into powder.

Features

1.Composite separator improves the efficiency of the powder.

2. With the function of automatic lifting and falling , can realize no-load starting.

3. Welded type arc plate is used for sealing, it features simple structure, reliable performance, well-sealed structure.

4. By means of the roller swing-out device, the grinding rollers can be turned out of the mill, which is in favor of maintenance. 5. The limit mechanism avoids the fiction and crash of metals between grinding roller and grinding plate, increasing the rotating stability and security.

6. Operating pressure of hydraulic system is low, can reduce the leakage failure and the mill vibration , is good for operation and management.

7. The centralized circulating oil lubrication is applied to the grinding roller bearings, which ensures the bearing operate at constant temperature and with pure oil, so that longer service life is achieved.

Wording Principle

Material through the feed tube fell on the center of grinding plate, centrifugal force generated from the rotation of grinding plate uniformly scatters and flattens the materials outwards the surrounding area of grinding plate, to forms a certain thick layer of materials bed, the material was crushed by number of rollers at the same time. Driven by the continuous centrifugal force to keep the materials moving to the outer edge of the grinding plate, the materials off the grinding plate rising with the hot air which enter from wind ring into the mill, through the mill shell into the middle of the separator, in this course materials and hot gas do a fully heat exchange, and the water quickly evaporates. Separator controls the output size of finished product, greater than the specified size are separated and fall back to the plate, while meet the fineness requirements are brought through the separator into the finished product warehouse.

.jpg)